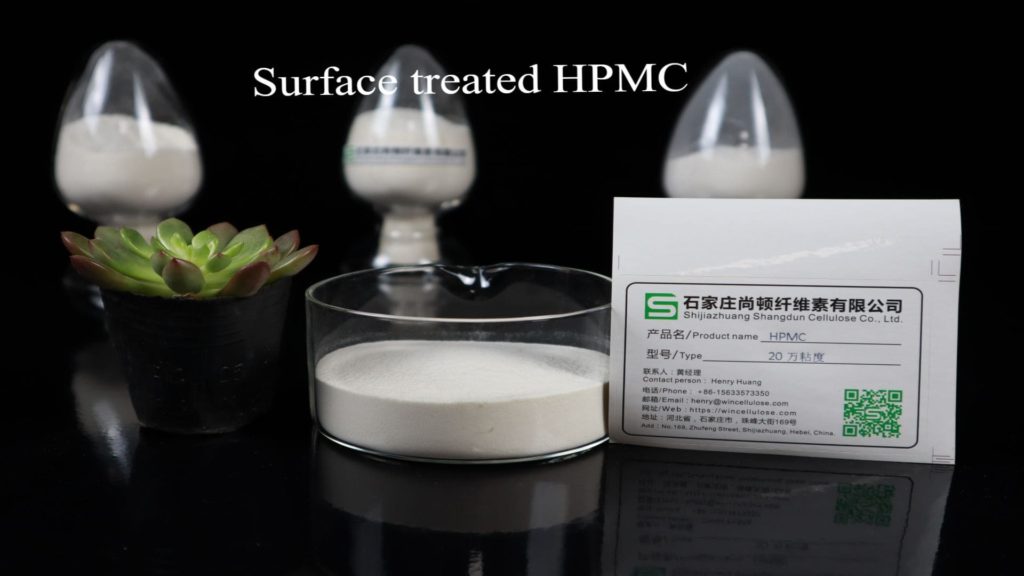

Usually, according to whether it could be dissolved in cold water or not, we divide HPMC into two types: surface treated HPMC and non-surface treated HPMC, and today, let’s introduce the surface treated HPMC first.

What is its other name

Beside surface-treated HPMC, it is also called delayed solubility/ hydration HPMC, instant soluble HPMC.

How is it made

We use a cross-linking agent (usually use glyoxal) to treat its surface in the production process, so the surface treated HPMC could disperse in cold water quickly, while not dissolve at first. And due to this extra process, it is a little expensive than the non-surface treated HPMC.

what is its strength

As it could be dissolved in cold water directly not like non-surface treated HPMC which has to be dissolved in hot water, surface treated HPMC could be used in more application areas, like glue and coating, detergent. And we could control the time of the HPMC becoming viscous by control the PH value of the solution, as you know, if you want to get it viscous slowly, then make an acidic environment of the solution.

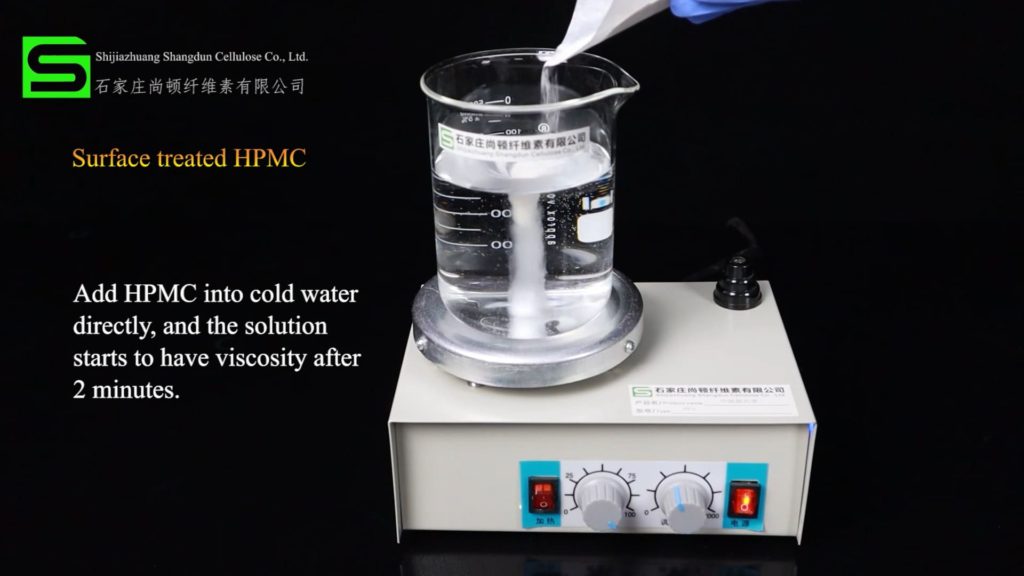

Why does it take some time to build up the viscosity when adding surface-treated HPMC into cold water?

when it is added into cold water, it would be dispersed in water quickly, not be dissolved, so the solution looks white, and it starts to build up viscosity after several minutes, and roughly after 30 minutes, the viscosity reach to the highest.

How to dissolve it

All we need to do is just put it into the water, while keep stirring. And you can click here to get more info about how to dissolve it.

Because of different application requirements, we have developed and made many different types of HPMC to meet the certain needs of different industries, so if you are looking for high quality HPMC products, just feel free to contace us, and it would be our pleasure to help you.