1. The name is different.

Surface treated HPMC is also called delayed solubility/hydration HPMC, instant soluble HPMC

Non-surface treated HPMC is also called slowly soluble HPMC, hot water soluble HPMC.

2. The production process is a little different

Actually, the Surface treated HPMC has one more procedure than the non-surface treated HPMC in the production process, and it’s adding a cross-linking agent to treat the surface of HPMC, so that the HPMC can be dispersed in cold water quickly.

3. The price is different

Because of the extra procedure in the production process, usually, the surface-treated HPMC is a little expensive than the non-surface treated HPMC.

4. Different ways of dissolution

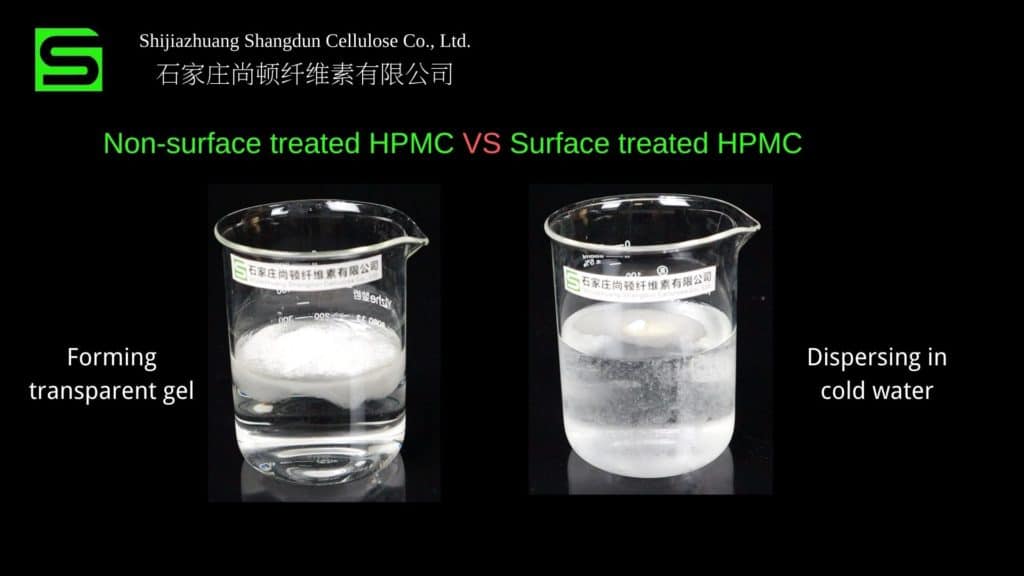

Surface treated HPMC:

We can just add it in the cold water gradually and keep stirring for about 30 minutes, because the HPMC is just dispersed in the water at first, so it takes some time to build up the viscosity until it’s totally dissolved in water.

Non-surface treated HPMC:

Because it will agglomerate when it’s put into cold water, but disperse in hot water, so we generally put it into hot water first, then make or wait for the temperature to cool down, and the trasparent viscous liquid is formed.

5. The application is a little different

Because the surface treated HPMC could be dissolved in cold water directly, it has a wider application area, it could not only be applied in wall putty, cement-based mortar, tile adhesive, but also could be used in glue and coating, detergent, and so on, so surface-treated HPMC has a wider application.

All right, this is all I’d like to share with you, if you need this kind of products, just feel free to contact us, hope we could help you in the future.